6. Fans in series

It happens that some industrial process avid of pressure, requires to place two fans in series. This arrangement might be used either because the pressure is high and the material used forbid to use a single fan stage, either because the user sees another advantage in using two machines in series

Indeed: It will be easier for the electricity network to hold the successive direct online start of 2 motors 160 kW rather than one motor 315 kW.

According the requested pressure, the user can also decide to work

sometimes with one fan, sometimes with both, saving energy.

In some cases, investing two fans in series at lower speed, and occupying fewer place will be financially more advantageous than one fan able of all the pressure alone. After the integration of a device with important pressure drop into the existing system, it will be necessary to add a fan in series with the existing fan.

each the impeller of both fans; a linking pipe join the outlet

of the 1st fan with the inlet of the 2nd

A typical case of high pressure demand is the installations of glass hardening furnace. The toughened glass is used as tempered safety glass for the cars, but also, for some household articles.

The hardening is produced by a violent cold air blowing on the items exiting the reheating furnace. The air pressure to be processed will be depending on the speed air we wish to get at the exit holes front of the scrolling glass items. This speed is itself depending on the thickness. For example, we can harden 5 mm thickness glass with average 500 daPa, but almost 2000 daPa are necessary for hardening a 3mm thickness glass (lateral car glass,…).

The flow to be processed depends indeed on:

- The blowing section, equal to the item to be harden,

- The air speed in this section

Operation points

For the easiness, we suppose that the fans are identical, the line of thought is identical for different fans.

The system curve is a parabola (the pressure loss are proportional to the square speed (Dp= k v²ρ/2g), and flow.

The equation of the system curve will take the form y=kx².

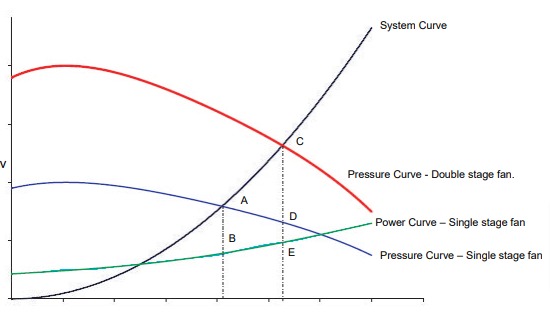

The first fan operating alone meet the system curve at the A point and requires a power equal to point B on the curve.

When we place the second fan in series with first one, the resulting curve flow-pressure is achieved by doubling the pressure value by each flow value. Therefore, the two fans together will met the system curve in C, each operating on the D point and absorbing a power on E point.

Remarks

- If a new fan is connected in series with the existing one, we observe that the operating point moves on the right side, comparing to the lonely operation. It is therefore necessary to check the sufficient installed

motor power, because in general the absorbed power increase proportionally with the flow. - In this thought line, we ignored the pressure drop of the pipe between the two fans. The pipe will certainly have elbows; we must add this extra pressure loss to the requested pressure for the process before to select the fans.

- When the requested pressures are really important, the air densities feeding the two fans are different, as well because of the air temperature increase between the 1st and 2nd stage (due to air compression), but also because of the different pressure level at the inlet of each fan. Practically, rather than to select two different fans, we prefer to take into account a middle value for the density, applied at the inlet of each identical fans processing about the half of the pressure each.